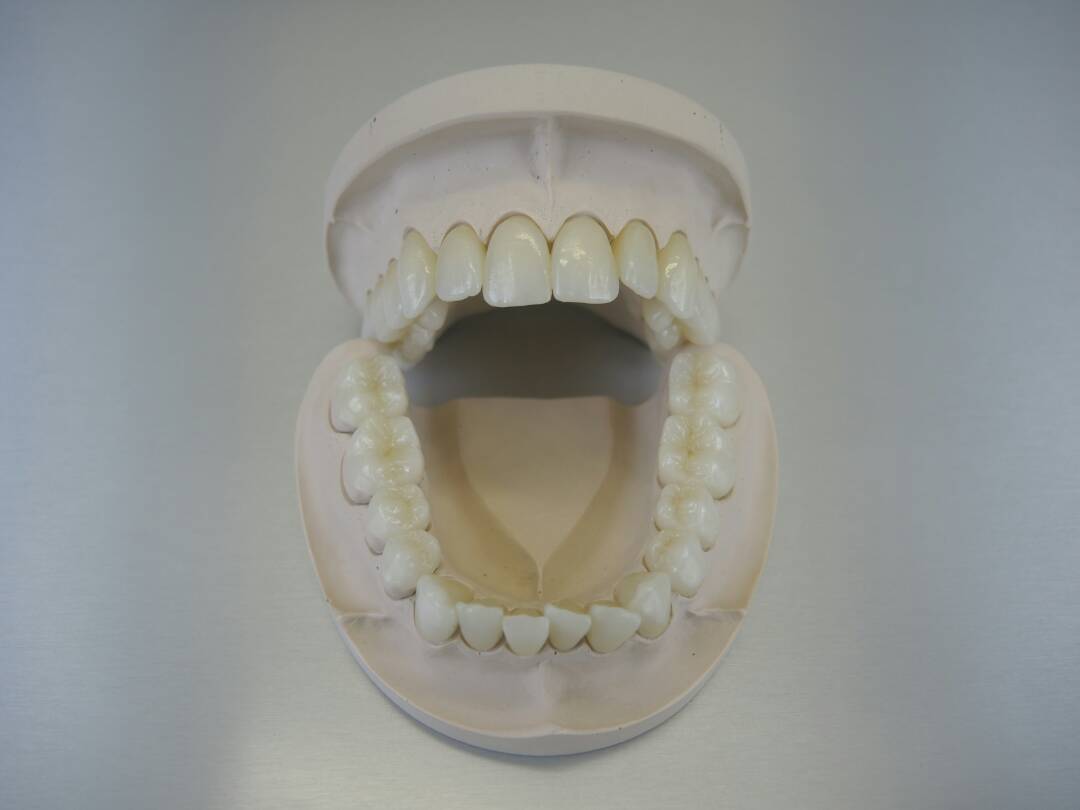

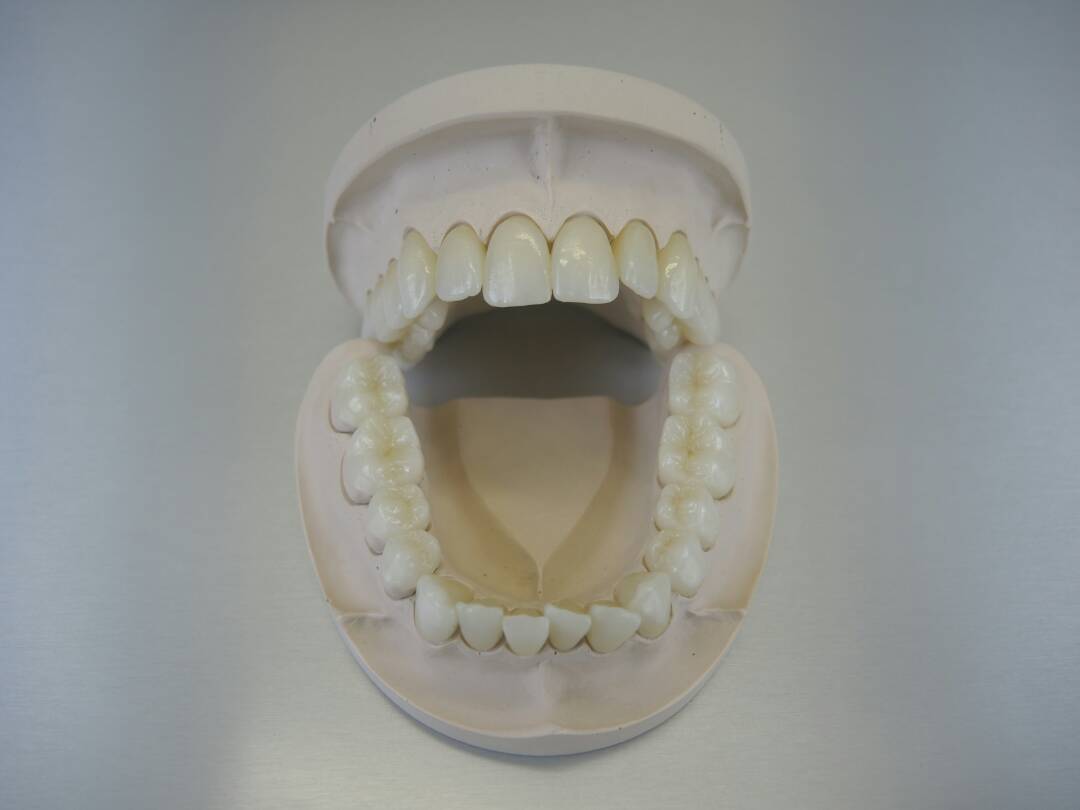

1.Ultra Translucent Zirconia blanks Introduction

Ultra Translucent Zirconia blanks are ideal for all highly esthetic treatments in the anterior area. In addition, they are also very suitable for use in the posterior area. Our Honchon UT, translucent like lithium disilicate - strong like zirconium oxide。Delivery time is 1-3 working days,Minimum order quantity can be negotiated, OEM is accepted。

Add WhatsApp Contact Now

2.Ultra Translucent Zirconia blanks Parameter

| Color: |

White |

| Aesthetic: |

Ultra Translucent |

| Sintered Density: |

6.0g/cm³ |

| Bending Strength: |

650Mpa |

| Light Transmittance: |

49% |

| Sintering Temperature: |

1450℃ |

3.Ultra Translucent Zirconia blanks Recommend Indications:

Inlay & Onlay & Partial Crown

Coping & Anterior Crown

Coping Bridge & Veneer

Full Contour Bridge ≤4 unit

4.Available sizes of Ultra Translucent Zirconia blanks:

|

Opening system

|

Amann Girrbach system

|

ZirkonZahn system

|

|

98*10mm

|

89*71*10mm

|

95*10mm

|

|

98*12mm

|

89*71*12mm

|

95*12mm

|

|

98*14mm

|

89*71*14mm

|

95*14mm

|

|

98*16mm

|

89*71*16mm

|

95*16mm

|

|

98*18mm

|

89*71*18mm

|

95*18mm

|

|

98*20mm

|

89*71*20mm

|

95*20mm

|

|

98*22mm

|

89*71*22mm

|

95*22mm

|

|

98*25mm

|

89*71*25mm

|

95*25mm

|

5.Product feature

Suitable for anterior restoration

Pefect match with HONCHON UT coloring shade liquid

Superior glassy translucency

6.Production Process

A. Raw material selection:

We carefully select high-purity zirconia powder produced in China. This zirconia powder manufacturer is the best factory in China. We maintain long-term cooperation to ensure the performance of raw materials and adopt the industry's advanced yttria stabilization formula. To ensure that the finished product has excellent mechanical properties and stable product quality, this formula has been improved and iterated many times, and now the product quality is excellent.

B. Mixing and Layering:

Since in the product formula of zirconia, the main component used to achieve color is alumina. The higher the proportion of alumina, the more yellow the color will be. Therefore, to achieve a gradient change in color, the alumina component is gradually reduced. After this treatment, the zirconia powder is mixed with pigments of varying strengths to create a multi-layered effect. Each layer is designed to replicate the natural gradient and translucency of human teeth.This step is not required if white zirconia and pre-colored zirconia are produced.

C. Cold isostatic pressing:

This process mainly involves placing the mixed raw materials into a static press device and applying appropriate pressure. Note that the pressure at this time is to apply uniform pressure from all directions to produce high-density blocks with excellent strength and uniform composition.

D. Pre-sintering:

The pressed blocks undergo a pre-sintering process at controlled temperatures to remove any organic binders and further increase the density and stability of the material. This sintering process is pre-sintering and must not be confused with the zirconia blocks before they become dentures. A sintering process is also required, and the sintering temperature is generally around 1500°.

F. Quality control:

Throughout the production process, we implement strict quality control measures in accordance with the ISO13485 quality management system to ensure that each multi-layered zirconia 4D star block meets the highest standards of strength, beauty and reliability.

G. Packaging and delivery:

Our products are available in custom sizes and custom packaging boxes. Once the products pass stringent quality checks, they are carefully packaged and ready for delivery to our customers, ensuring they receive a quality product that meets their expectations.

We are a professional zirconia manufacturer with 10+ experience. The factory has a very strict quality management system, has multiple certifications, and the product praise rate is as high as 99%.

Note : you are using the system Zirkonzahn and Amann Girrbach system. We can provide the compatible size for your system. Please contact us : info@honchon.com

Instruction of our HONCHON UT and sintering temperature, please download at our site.

You Might Also Like