Dental zirconia blocks are a cornerstone in modern dentistry, recognized for their strength, durability, and aesthetic appeal. These blocks, made from zirconium dioxide (ZrO₂), are primarily used in the creation of dental restorations such as crowns, bridges, and veneers. Their ability to closely mimic natural teeth while providing long-lasting results has made zirconia a material of choice in the dental industry.

Material Purity: High-quality dental zirconia blocks are made from premium-grade zirconia powder, ensuring uniform particle size and distribution. This purity is essential for achieving the desired strength, translucency, and biocompatibility.

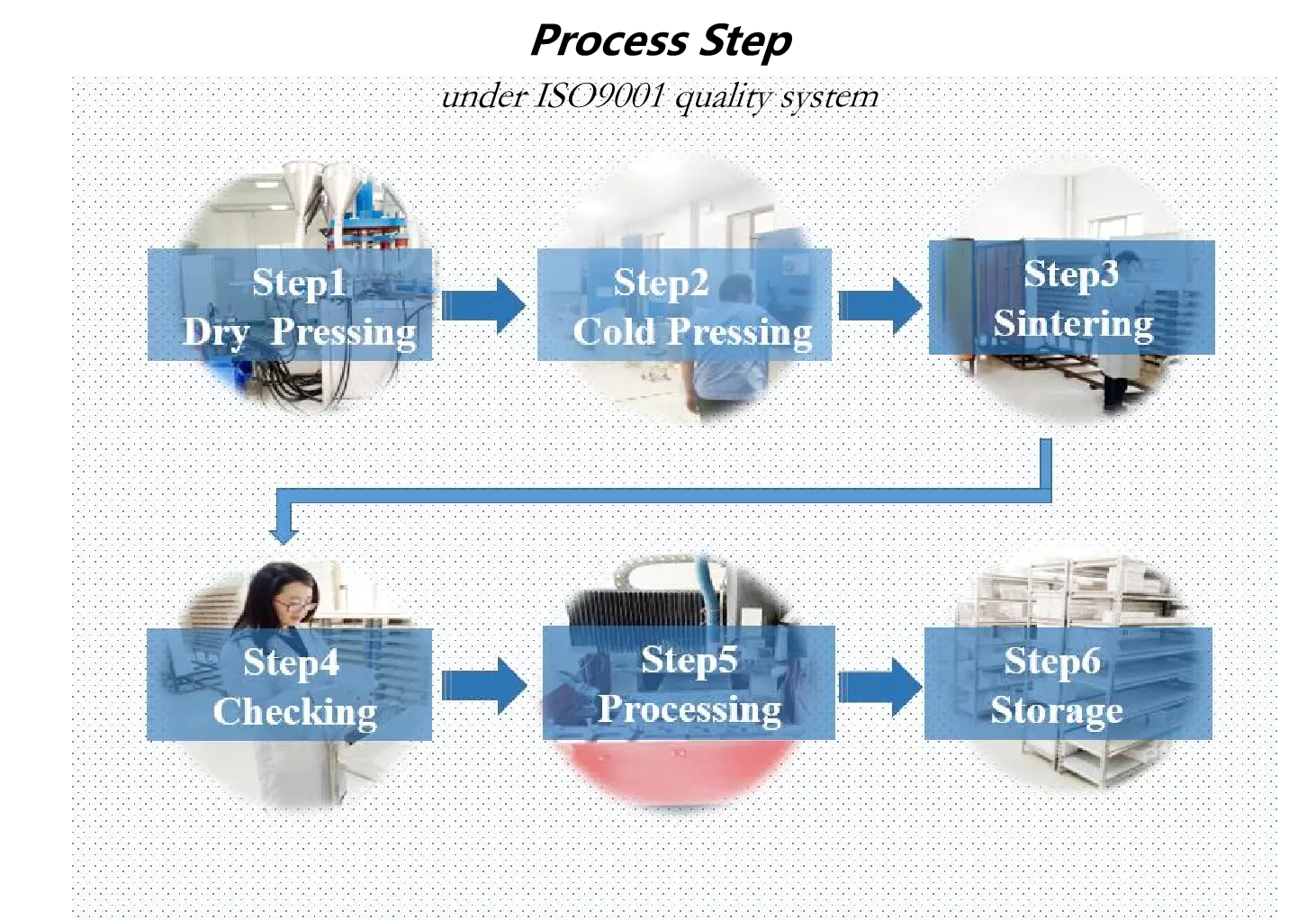

Manufacturing Standards: The quality of dental zirconia blocks is heavily influenced by the manufacturing process. Precise control of sintering temperatures, advanced pressing techniques, and rigorous quality inspections are crucial for producing blocks that meet industry standards.

Product Consistency: For B2B clients, consistency in the quality of zirconia blocks is paramount. This involves uniformity across batches, ensuring that every block performs identically under similar conditions.

Crowns and Bridges: Dental zirconia blocks are extensively used for creating crowns and bridges, offering durability and an aesthetic finish that closely resembles natural teeth.

Inlays and Onlays: These blocks are also used for custom-made fillings that provide superior strength and longevity compared to traditional materials.

Veneers: Thin layers of zirconia are used to cover the front surface of teeth, providing cosmetic enhancements with long-lasting results.

Implants: Due to their high strength and biocompatibility, zirconia blocks are increasingly used in the fabrication of implant abutments.

Wholesale Pricing: When purchasing large quantities, understanding wholesale pricing structures is crucial. Bulk purchasing can offer significant cost advantages, but it requires careful negotiation and supplier management.

Supplier Reliability: For B2B clients, the reliability of the zirconia supplier is critical. Ensuring consistent supply, timely delivery, and consistent quality helps maintain uninterrupted production schedules.

Lead Times: Effective supply chain management includes understanding and managing lead times to align with production demands. This ensures that zirconia blocks are available when needed, without delays.

Custom Solutions: Many clients require customized zirconia blocks, tailored to specific dental applications. This can include custom shades, sizes, and levels of translucency to meet unique patient needs.

Milling Precision and Efficiency: In the fabrication of dental restorations, the precision and efficiency of milling machines are paramount. 5-axis dental milling machines used in processing zirconia blocks offer high precision, faster production times, and the ability to handle Complex geometry, ensuring that restorations meet exact specifications.

High Strength: Zirconia blocks offer exceptional strength, making them suitable for load-bearing restorations that require durability.

Aesthetic Appeal: The natural translucency of zirconia allows for restorations that closely mimic the appearance of real teeth, enhancing the overall aesthetic.

Biocompatibility: Zirconia is highly biocompatible, reducing the risk of allergic reactions or adverse tissue responses, which is crucial for patient safety.

Longevity: Restorations made from zirconia blocks are known for their long-term durability, providing a lasting solution for patients.

Cost: Zirconia blocks are more expensive compared to other dental materials, which may impact pricing strategies for dental practices.

Processing Challenges: Due to their hardness, zirconia blocks require advanced milling equipment and skilled technicians to ensure accurate and smooth finishes, which can increase processing time and costs.

Changsha HONCHON Technology Co., Ltd. is a leader in the production of dental zirconia blocks, offering a range of products that meet the highest industry standards. Here’s why B2B clients should consider partnering with us:

State-of-the-Art Manufacturing: We use cutting-edge technology and strict quality controls to produce zirconia blocks that excel in both performance and aesthetics, ensuring each block meets the rigorous demands of dental professionals.

Extensive R&D: Our dedicated research and development team continuously innovates to enhance the properties and applications of our zirconia products, staying ahead of industry trends.

Global Reach: With a strong presence in over 200 countries, we have the capacity and experience to support clients worldwide, ensuring reliable supply and support no matter where you are.

Customized Solutions: We offer tailored zirconia blocks to meet the specific needs of our clients, ensuring the best possible outcomes for their dental practices.