Introduction

In today's dental restoration field, the choice of materials is crucial to treatment results and patient experience. Dental Zirconia Blocks has gradually become one of the preferred materials in dental restorations due to its excellent performance and diverse application areas. This article will conduct a comprehensive analysis of Dental Zirconia Blocks, from its scientific basis to clinical applications, as well as the perspectives of patients and doctors, to provide readers with an opportunity to gain a deeper understanding of this material.

Part I: The Scientific Basis of Zirconia

In this part, we will take a deep look at the scientific basis of Zirconia (zirconia) as a dental restorative material, including its chemical and physical properties and comparisons with other dental materials.

Chemical and Physical Properties of Zirconia

Chemical and Physical Properties of Zirconia

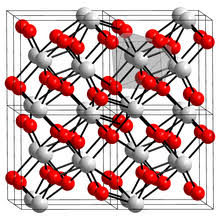

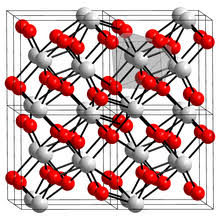

Zirconia is a ceramic material with the chemical formula ZrO₂, composed of two elements: zirconium and oxygen. Its crystal structure can change depending on the temperature and pressure, and the most common crystal structures include monoclinic and cubic crystals.

1. **Stability of Crystal Structure**: The crystal structure of Zirconia exhibits different stabilities in different environments. At room temperature and pressure, Zirconia has a monoclinic crystal structure, while under high temperature or high pressure conditions, it will transform into a cubic crystal structure. This change in crystal structure affects the physical properties and application range of Zirconia.

2. **Hardness and Compression Resistance**: Zirconia has excellent hardness and compression resistance, making it an excellent dental restorative material. Its hardness is close to that of natural teeth, which can effectively resist the pressure during chewing while maintaining the integrity of the restoration.

3. **Fracture resistance**: Zirconia has excellent fracture resistance and is not prone to fracture even under extreme conditions. This property enables it to withstand large loads in dental restorations and has a long service life.

4. **Chemical stability**: Zirconia has good chemical stability because its chemical structure is stable and it is not easy to react chemically with other substances. This allows Zirconia to exist stably in the mouth for a long time and is not easily eroded by acid and alkali environments.

Comparison of Zirconia with other dental materials

As a dental restoration material, Zirconia has many advantages over traditional metals and other ceramic materials.

1. **Aesthetic effect**: Zirconia has excellent aesthetic effects. Its color and texture are close to natural teeth and can blend with surrounding tissues to achieve better aesthetic effects. In contrast, metal restorations often appear gray or metallic, which affects aesthetics.

2. **Biocompatibility**: Zirconia has good biocompatibility, is not prone to allergic reactions or other adverse reactions, and has less irritation to oral tissues. This allows Zirconia restorations to integrate well with surrounding soft and hard tissues, reducing the occurrence of postoperative complications.

3. **Hardness and wear resistance**: Zirconia has excellent hardness and wear resistance, can effectively resist wear and pressure during chewing, and has a long service life. In contrast, although metal restorations have high hardness, they are prone to wear against tooth enamel, and ceramic restorations may crack due to material fragility.

4. **Adaptability and precision**: Zirconia can be precisely produced through CAD/CAM technology, which can achieve highly personalized restorations to adapt to the oral conditions of different patients. This greatly improves the adaptability and precision of Zirconia restorations, greatly reducing the need for postoperative adjustments and re-repairs.

In summary, Zirconia, as a dental restoration material, has unique chemical and physical properties that make it perform well in dental restorations. Compared with traditional metals and other ceramic materials, Zirconia has better aesthetic effects, biocompatibility, hardness and wear resistance, as well as higher adaptability and precision, and has therefore received widespread attention and application.

In this part, we will introduce in detail the manufacturing process of Dental Zirconia Blocks and the application of CAD/CAM technology in Zirconia processing. The development and application of these technologies are of great significance to improving the precision, quality and efficiency of restorations.

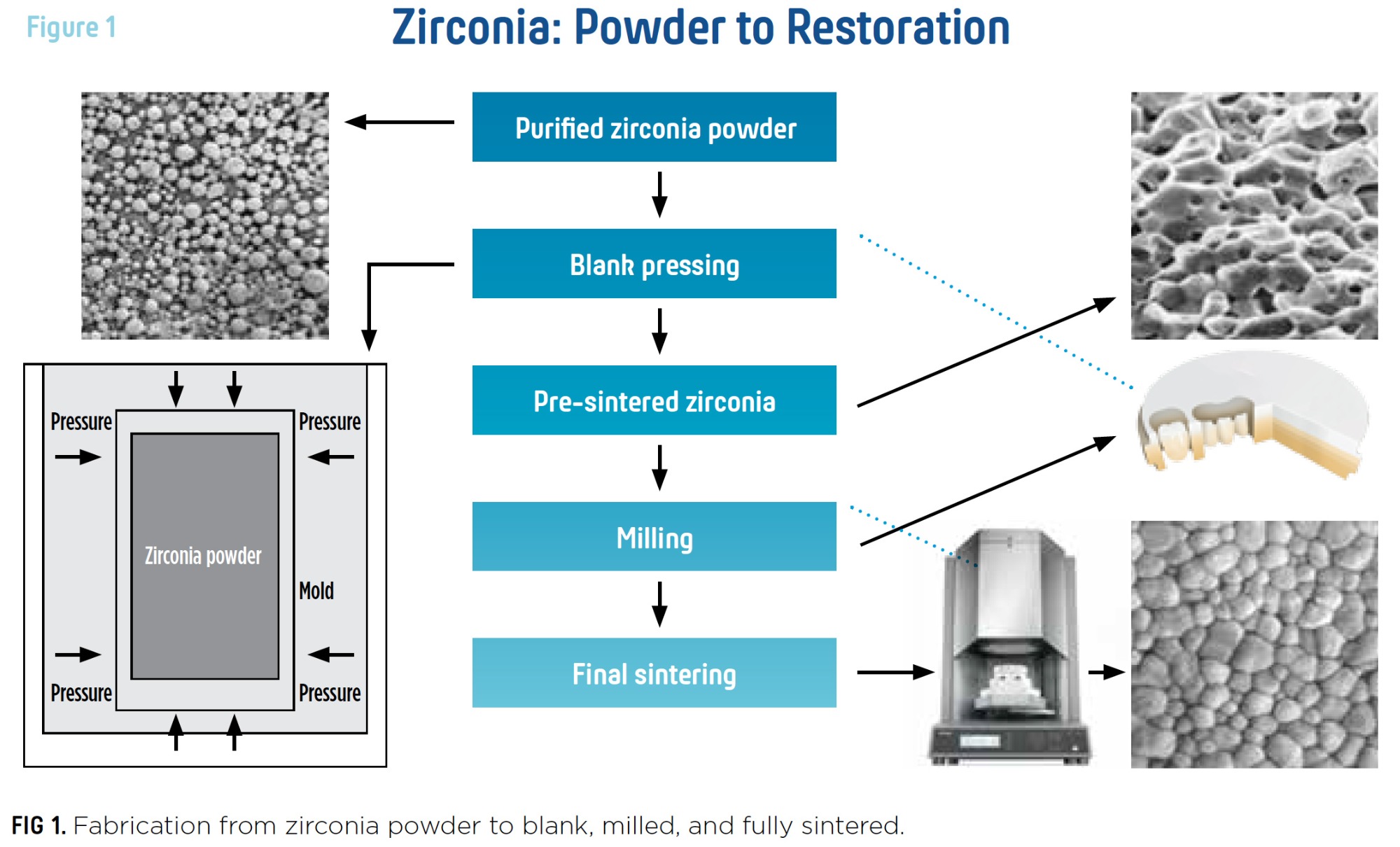

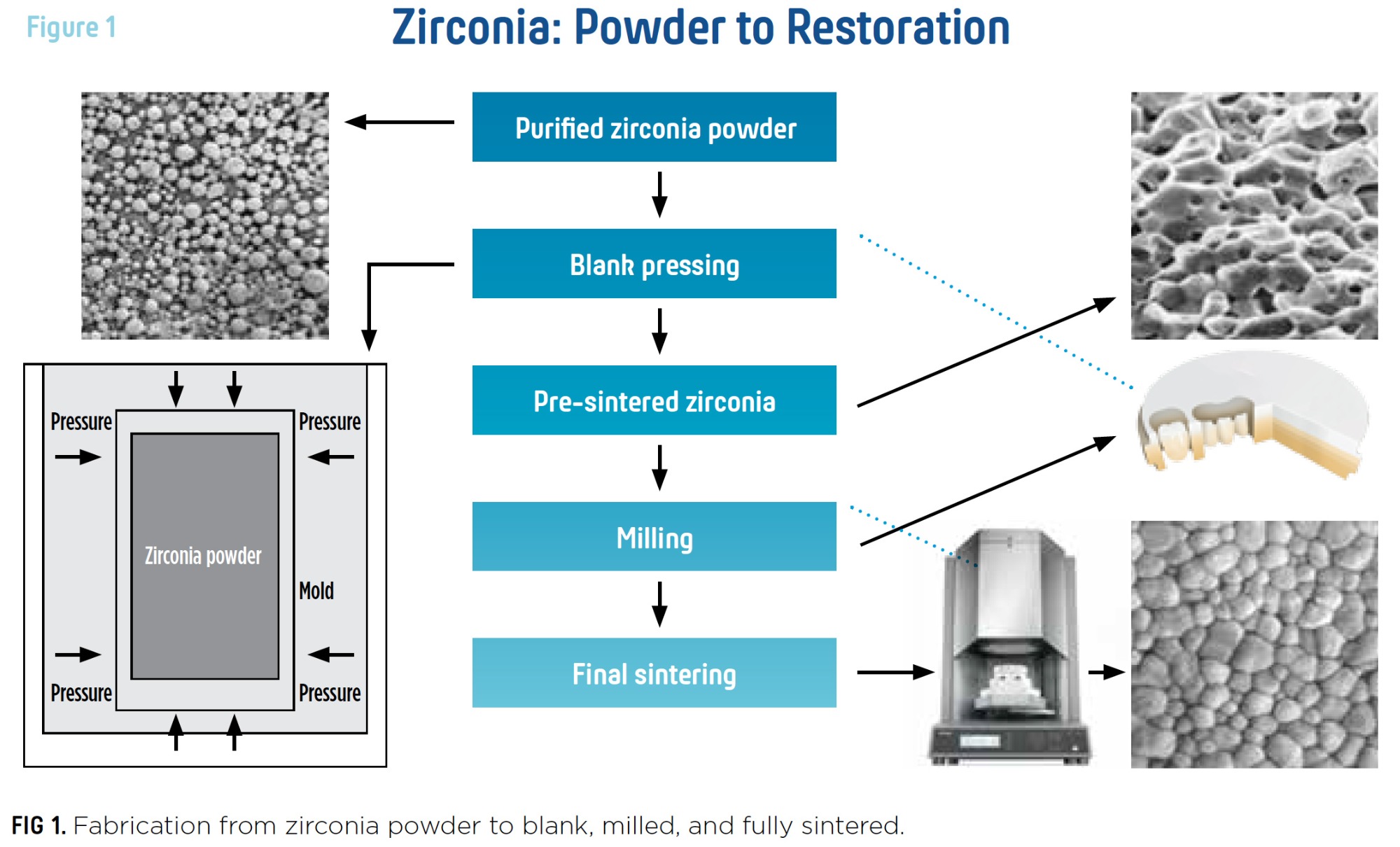

Production process

The manufacturing process of Dental Zirconia Blocks is a complex and sophisticated project involving precision control of multiple links and the use of high-quality raw materials.

1. **Selection of raw materials**: The first step in manufacturing high-quality Zirconia Blocks is to select high-quality raw materials. Commonly used raw materials include zirconium oxide powder, stabilizer, color powder, etc. The quality and purity of these raw materials have an important impact on the performance and stability of the final product.

2. **Mixing of raw materials**: The selected raw materials need to be precisely mixed to ensure that the proportion and distribution of each component are uniform. This is usually achieved by dry or wet mixing, ensuring the uniformity and stability of Zirconia Blocks.

3. **Molding**: The mixed raw materials need to be molded in order to make Zirconia Blocks with specific shapes and sizes. The molding method can adopt different processes such as injection molding and compression molding. The appropriate method should be selected according to the needs and design of the product.

4. **Sintering**: Sintering is the most critical step in the entire manufacturing process, which determines the density, strength and compactness of the final product. Under high temperature and pressure, the particles of Zirconia Blocks will combine with each other to form a solid structure. The control of sintering temperature and time is very important and needs to be precisely controlled to ensure product quality.

5. **Processing and surface treatment**: Zirconia Blocks after sintering need to be precisely processed and surface treated to meet different clinical needs and aesthetic requirements. This includes processes such as grinding, polishing, sandblasting, and surface treatments such as coating ceramic layers or glazes.

The production process of Dental Zirconia Blocks requires strict quality control and advanced production equipment. The application of modern technology has significantly improved production efficiency while also ensuring product quality and stability.

Application of CAD/CAM technology in Zirconia processing

Application of CAD/CAM technology in Zirconia processing

CAD/CAM technology has become one of the standard tools in modern dental restorations, and is of great significance for the manufacturing and processing of Zirconia Blocks.

1. **Computer-aided design (CAD)**: CAD technology accurately measures and analyzes the patient's oral condition in a digital way, providing an accurate data basis for subsequent restoration design. Doctors can make personalized designs based on the patient's oral condition, including design in terms of shape, size, aesthetic effect, etc.

2. **Computer-aided manufacturing (CAM)**: CAM technology uses CAD design data and performs precise processing through CNC machine tools to achieve highly customized restoration production. CAM technology can achieve precise processing of Zirconia Blocks, including cutting, grinding, polishing and other processes, ensuring the accuracy and quality of the restoration.

The application of CAD/CAM technology not only improves the accuracy and quality of restoration, but also shortens the production cycle and improves work efficiency. At the same time, CAD/CAM technology also provides doctors and technicians with more design and processing options, making the restoration plan more flexible and diverse.

In summary, the manufacturing and processing of Dental Zirconia Blocks is a complex and sophisticated process involving precision control of multiple links and the application of high-tech equipment. The development of modern technology has made the manufacturing process more efficient, precise and stable, providing patients with better dental restoration services. The application of CAD/CAM technology has further improved the accuracy and quality of restorations, bringing new opportunities and challenges to the development of the dental restoration field.

Part III: Clinical Application of Dental Zirconia Blocks

In this part, we will explore in detail the clinical application of Dental Zirconia Blocks in crowns, bridges, implants and other dental devices, including the design, manufacturing, installation process, and long-term performance and maintenance requirements.

Crowns and Bridges

**Design, Manufacturing and Installation Process:**

1. **Oral Scanning and Digital Design**: Before crown and bridge restoration, the patient's oral cavity needs to be scanned to obtain digital oral data. This data can be obtained through an oral scanner and digitally designed using CAD software. The doctor can design a restoration that meets anatomical and aesthetic requirements based on the patient's oral condition and needs.

2. **Manufacturing of Zirconia Blocks**: Zirconia Blocks are precisely processed using CAM technology based on CAD design data. This usually includes cutting Zirconia Blocks into appropriate sizes and shapes, and fine grinding and polishing to ensure the quality and fit of the restoration.

3. **Trial-in and adjustment**: The manufactured Zirconia crowns and bridges will be trial-fitted, and the doctor will check their fit and stability with the surrounding tissues, and make necessary adjustments to ensure the coordination of the restoration with the surrounding teeth and soft tissues.

3. **Trial-in and adjustment**: The manufactured Zirconia crowns and bridges will be trial-fitted, and the doctor will check their fit and stability with the surrounding tissues, and make necessary adjustments to ensure the coordination of the restoration with the surrounding teeth and soft tissues.

4. **Permanent installation**: After the trial-in and adjustment are completed, the Zirconia crowns and bridges will be permanently installed in the patient's mouth. The doctor will use dental glue or dental cement to firmly bond the restoration to the tooth or implant to ensure its stability and functionality.

**Long-term performance and maintenance requirements:**

1. **Wear resistance and stability**: Zirconia crowns and bridges have excellent wear resistance and stability, can withstand the chewing force and pressure in the mouth, and have a long service life.

2. **Aesthetic effect**: Due to the good transparency and color stability of Zirconia materials, the manufactured crowns and bridges can achieve good color and texture consistency with natural teeth, and have good aesthetic effects.

3. **Oral hygiene**: The surface of Zirconia crowns and bridges is smooth and not easy to absorb bacteria, which is convenient for oral hygiene maintenance. Patients need to perform regular oral cleaning and examinations to ensure the stability and health of the restoration.

Implants and other applications

**Use of Zirconia in dental implants**:

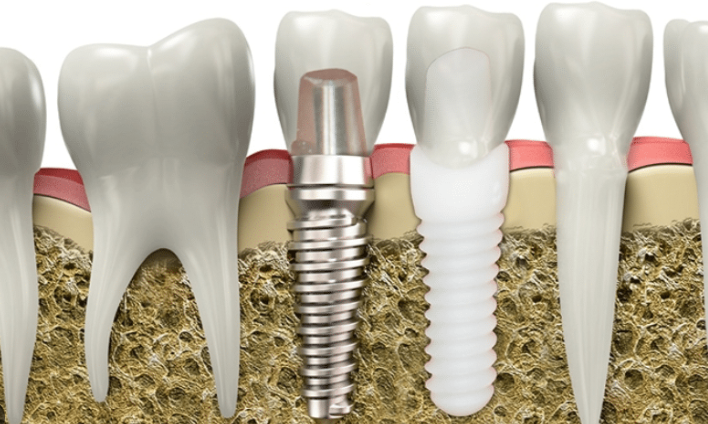

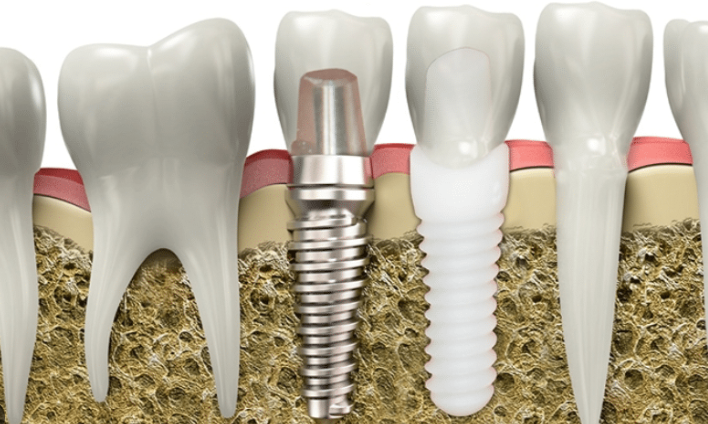

1. **Types and designs**: Zirconia implants are usually divided into two parts: the implant and the restoration on the implant. The implant is surgically implanted into the patient's jawbone as a replacement for teeth or alveolar bone. The restoration is installed on the implant to support and fix artificial teeth or restorations.

2. **Advantages and applications**: Zirconia implants have excellent biocompatibility and mechanical properties, can be well integrated with surrounding tissues, and reduce the occurrence of postoperative complications. Its high strength and wear resistance enable the implant to withstand the pressure and chewing force in the mouth and have a long service life.

2. **Advantages and applications**: Zirconia implants have excellent biocompatibility and mechanical properties, can be well integrated with surrounding tissues, and reduce the occurrence of postoperative complications. Its high strength and wear resistance enable the implant to withstand the pressure and chewing force in the mouth and have a long service life.

**Application of Zirconia in other dental equipment**:

1. **Nighttime grinding plate**: Zirconia material has excellent wear resistance and stability, and is suitable for making nighttime grinding plates. This type of grinding plate can protect the patient's teeth from damage caused by nighttime grinding, while having good comfort and adaptability.

2. **Orthodontics**: Zirconia material can be used to make orthodontics to correct the position and occlusion of teeth. Its high strength and adaptability enable orthodontics to provide stable correction force and achieve ideal correction effect.

In summary, Dental Zirconia Blocks have a wide range of clinical applications in crowns, bridges, implants and other dental devices. Its excellent physical and chemical properties make Zirconia restorations have excellent long-term performance and stability, which can meet the functional and aesthetic needs of patients. With the continuous advancement of science and technology, it is believed that the application of Zirconia in the field of dentistry will be more extensive and in-depth.

Part 4: Patient and Doctor Perspectives

In this part, we will explore the use and experience of Dental Zirconia Blocks from the perspectives of patients and doctors, including patient case studies and insights from doctors and technicians.

Patient Case Studies

**Patient A: Mary**

Mary is a young woman who came to the clinic because of a severely decayed back tooth. After the doctor's examination and advice, she decided to use Zirconia Blocks for restoration. After the treatment, Mary felt that the texture and color of the restoration were very similar to the surrounding teeth and were almost indistinguishable. She was very satisfied with the treatment results and said that she no longer had to worry about her smile being unconfident.

Mary is a young woman who came to the clinic because of a severely decayed back tooth. After the doctor's examination and advice, she decided to use Zirconia Blocks for restoration. After the treatment, Mary felt that the texture and color of the restoration were very similar to the surrounding teeth and were almost indistinguishable. She was very satisfied with the treatment results and said that she no longer had to worry about her smile being unconfident.

**Patient B: John**

John is a middle-aged man who came to the clinic because of loose teeth caused by injuries to his front teeth. The doctor recommended that he use Zirconia Bridges for restoration to restore the function and beauty of his teeth. After a period of treatment, John felt that the restoration was very stable and adaptable, and could meet his daily life and chewing needs. He was very satisfied with the treatment results and said that he would recommend it to his friends.

John is a middle-aged man who came to the clinic because of loose teeth caused by injuries to his front teeth. The doctor recommended that he use Zirconia Bridges for restoration to restore the function and beauty of his teeth. After a period of treatment, John felt that the restoration was very stable and adaptable, and could meet his daily life and chewing needs. He was very satisfied with the treatment results and said that he would recommend it to his friends.

**Patient C: Amy**

Amy is an older woman whose chewing and speaking functions were affected by years of tooth loss. The doctor recommended that she undergo Zirconia implants for implantation and restoration. After a period of treatment and rehabilitation, Amy felt that the implants were very stable and adaptable, and were able to effectively restore the function and beauty of the teeth. She was very satisfied with the treatment results and regained her confident smile.

Amy is an older woman whose chewing and speaking functions were affected by years of tooth loss. The doctor recommended that she undergo Zirconia implants for implantation and restoration. After a period of treatment and rehabilitation, Amy felt that the implants were very stable and adaptable, and were able to effectively restore the function and beauty of the teeth. She was very satisfied with the treatment results and regained her confident smile.

Insights from doctors and technicians

**Doctor D: Dr. Zhang**

Dr. Zhang is a senior dentist who has been using Zirconia Blocks for restorative treatment for a long time. He believes that Zirconia Blocks have excellent physical properties and biocompatibility, and can provide high-quality restoration results. Through CAD/CAM technology, he is able to achieve precise design and manufacturing of restorations and provide personalized treatment plans for patients. He is very satisfied with the application and results of Zirconia Blocks and will continue to promote and apply them.

**Technician E: Technician Wang**

Technician Wang is a dental technician who is responsible for the processing and production of Zirconia Blocks. He believes that Zirconia Blocks have good processing performance and stability, and can achieve precise processing and high-quality production. Through CAD/CAM technology, he can produce restorations that meet the needs of patients according to the doctor's design requirements and provide patients with satisfactory restoration results. He has rich experience in the processing and application of Zirconia Blocks, providing doctors with reliable technical support.

Zirconia's position in dental education and training

As a revolutionary dental restoration material, Zirconia has been widely used and promoted in dental education and training. Many dental schools and training institutions have incorporated Zirconia restoration technology into the curriculum to cultivate students' understanding and application capabilities of Zirconia Blocks. Through theoretical teaching and practical operation, students can master the basic principles and operation skills of Zirconia restoration technology, laying a good foundation for future clinical practice.

At the same time, some professional dental training institutions have also opened professional courses and training courses for Zirconia restoration technology, and carried out in-depth training and practical operation for clinicians and technicians. Through systematic training and case study, doctors and technicians can further improve their understanding and application of Zirconia Blocks and provide patients with better dental restoration services.

In summary, patients and doctors have very positive feedback on the application and experience of Dental Zirconia Blocks. After treatment, patients felt the stability and aesthetic effect of the restoration and were very satisfied with the treatment results. Doctors and technicians also achieved good results when applying Zirconia Blocks, believing that it has excellent physical and processing properties and can meet clinical needs. At the same time, Zirconia's position in dental education and training has also been valued and promoted, providing important support for the technical improvement and development of dental professionals.