A dental zirconia block is a high-performance dental restoration material used primarily for making crowns, bridges, and other prosthetics. It is made from zirconium oxide (ZrO₂) through a high-temperature sintering process, resulting in a material that is both strong and durable. Dental zirconia blocks are popular in modern dental restorations because they provide a natural appearance similar to real teeth while ensuring long-term stability and reliability.

The quality of dental zirconia blocks is primarily reflected in the purity of the material, its density, and the manufacturing process. High-quality zirconia blocks should have uniform material distribution and excellent physical properties, including high strength, hardness, and compressive resistance. The raw materials used in the manufacturing process must be carefully selected to ensure the final product's superior quality. Additionally, each step of the production process, including powder preparation, mold pressing, and sintering, must be precisely controlled to meet high standards.

Dental zirconia blocks are mainly used for creating dental crowns, bridges, inlays, onlays, and other restorative components. Their robust nature makes them suitable for various dental restorations where strength and durability are crucial. The material is often chosen for its ability to withstand significant chewing forces and its resistance to wear and tear. Additionally, the aesthetic properties of zirconia allow for natural-looking restorations that blend seamlessly with the patient's existing teeth.

Dental zirconia offers several advantages, including exceptional strength and durability, which make it ideal for long-term dental restorations. It is highly resistant to fracture and chipping, ensuring that restorations remain intact under normal chewing forces. Zirconia also provides excellent biocompatibility, meaning it is well-tolerated by the body and does not cause adverse reactions. Furthermore, its aesthetic properties allow for a natural appearance that closely mimics real teeth.

While dental zirconia has numerous benefits, it also has some drawbacks. The material can be more challenging to work with compared to other materials due to its hardness, which may require specialized equipment for machining. Additionally, zirconia may not always achieve the same level of translucency as natural teeth. These challenges can sometimes increase the cost and complexity of dental procedures involving zirconia.

1. The company uses advanced production technology including industry-leading CIP technology, pre-sintering technology to ensure that each zirconia block meets international standards.

2. Strict quality control is implemented throughout the manufacturing process, from raw material selection to final product inspection.

3. The company has a professional and experienced technical team dedicated to providing quality products and services.

4.With R&D center providing CAD/CAM technology.

Our CAD/CAM technology and zirconia blocks provide design, technical guidance, problem solving, after-sales and training services to dental professionals and dentists for patients.

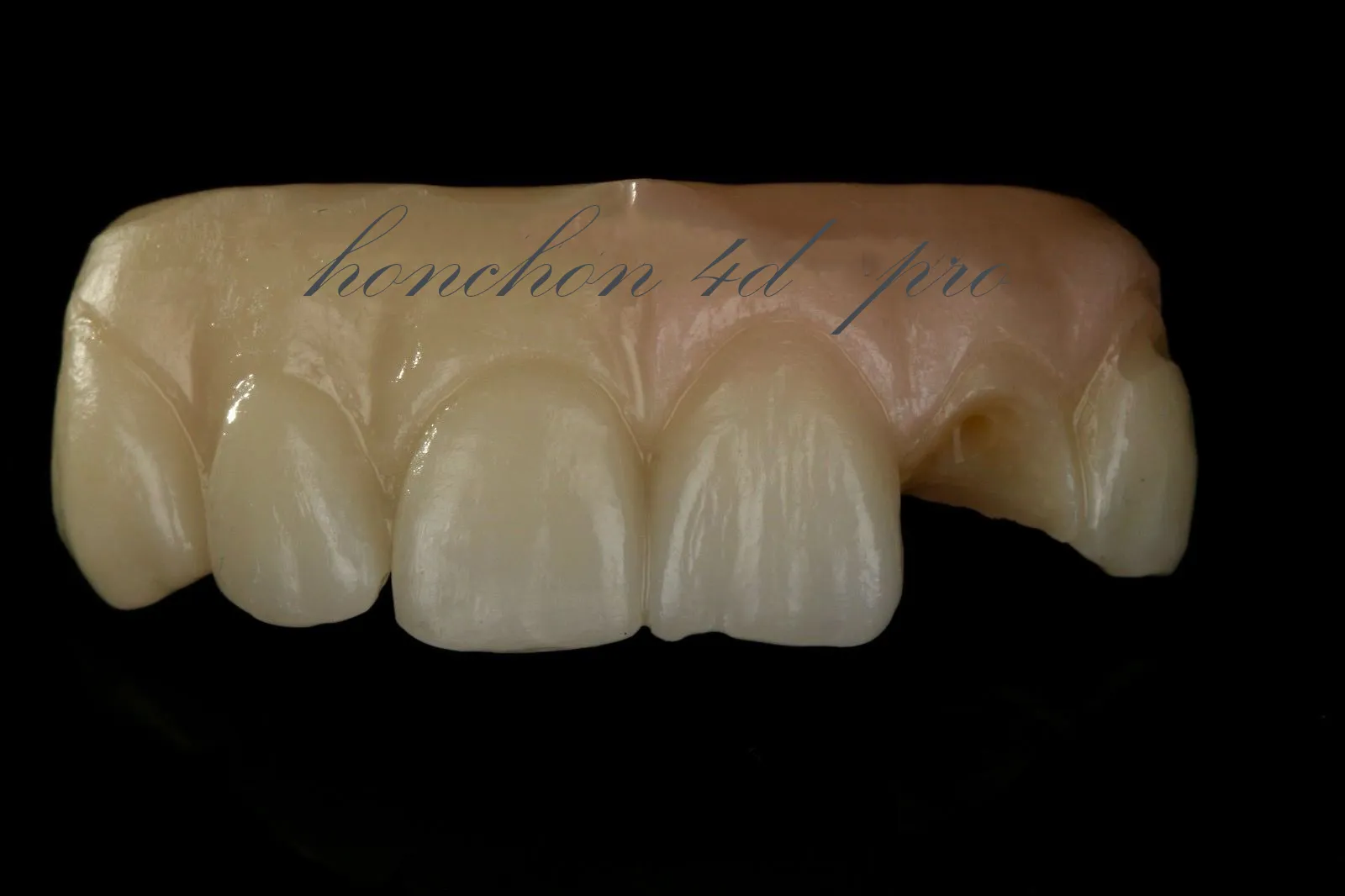

HONCHON 4D Pro ML is the result of more than 10 years of research on the properties of lithium disilicate in elderly, young, middle-aged and children from more than 100 countries. HONCHON 4D Pro ML offers color gradient with excellent incisal transparency. The color change occurs naturally near the incisal tip, from 45% to 57%. The incisal effect ensures light transmittance of the enamel and very effective light-shielding effect color in the neck with low light transmittance. HONCHON 4D Pro ML has excellent anti-aging properties. The unique combination product of TZP molecules and PSZ molecules effectively resists the degradation of zirconium oxide to cubic monoclinic phase. Flexural strength exceeds 800 Mpa in five years. The flexural strength of HONCHON 4D Pro ML(ML) naturally transitions between 800 MPa and 1200. The ultra-high strength bend can prevent chipping and cracking during processing and use, reducing the chance of rework. It is suitable for full-mouth bridges and implant bridges.

Dental zirconia is widely used in various dental applications, including the creation of crowns, bridges, inlays, onlays, and dental implants. Its high strength and resistance to wear make it suitable for both anterior and posterior restorations. Additionally, zirconia is used in digital dentistry for CAD/CAM applications, where its precision and durability are highly valued. The material's versatility and reliable performance make it a popular choice for dental professionals looking to provide high-quality restorations to their patients.