Dental CAD/CAM milling machines have revolutionized how dental restorations—such as crowns, veneers, inlays/onlays, and bridges—are designed and fabricated. Similar to their use in other manufacturing fields, these machines use advanced digital technology to create a precise virtual model of a restoration and then manufacture it with exceptional accuracy. This cutting-edge technology is reshaping dental practices by offering faster, more accurate, and more convenient solutions for custom dental restorations. By the end of this article, you will understand the important role dental CAD/CAM milling machines play and the benefits they offer to both dental professionals and patients.

Computer-Aided Design (CAD) refers to the use of computer software to create a detailed and precise three-dimensional model of a product. In dentistry, CAD allows dentists and technicians to design restorations like crowns, bridges, veneers, and other prosthetics digitally. A digital scanner captures a highly accurate image of the patient’s teeth, which is imported into CAD software and converted into a 3D model. The dental professional can then design a custom restoration that perfectly fits the patient's mouth, considering shape, size, and color.

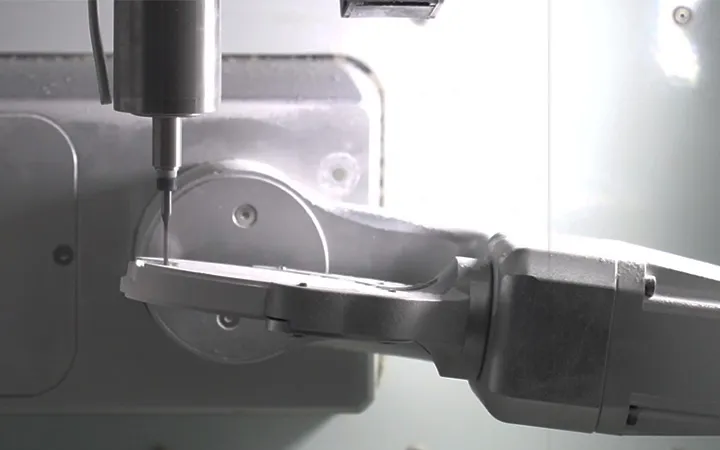

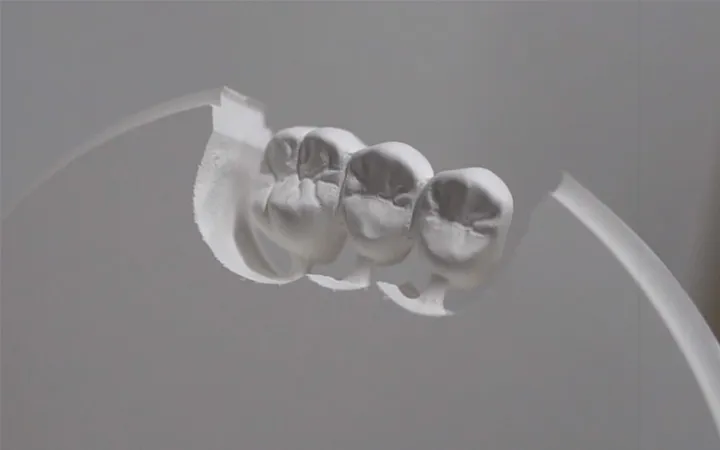

Once the design is complete, the data is sent to the CAM system, which controls the milling machine. The milling machine carves the restoration from a solid block of dental material such as zirconia, ceramic, or resin. This process ensures the final physical product matches the digital design precisely, resulting in restorations that fit comfortably and look natural.

Dental CAD/CAM milling machines are essential for producing precise and customized dental restorations including crowns, bridges, veneers, inlays/onlays, and implant abutments. The process begins with a digital scan capturing the exact dimensions of the patient’s teeth and gums, which is then used to design the restoration digitally.

Efficiency and Speed: CAD/CAM enables same-day restorations, drastically reducing treatment time.

Precision: Digital design ensures restorations fit perfectly with minimal adjustments.

Patient Comfort: Digital impressions are more comfortable than traditional molds.

Customization: Restorations are tailored to the unique anatomy of each patient.

Using an intraoral scanner, a 3D image of the patient’s mouth is captured. This digital model is then used in CAD software to design the restoration with accurate size, shape, and color matching the patient’s teeth.

The digital design data guides the CAM-controlled milling machine, which carves the restoration from a block of dental material using precise cutting tools. The materials are biocompatible and designed to mimic natural teeth.

Ceramics: Known for their strength and natural aesthetics, ideal for visible teeth.

Zirconia: High-strength material for durable restorations, including bridges and crowns.

Resins: Often used for inlays and onlays, offering good durability and minimal wear on opposing teeth.

The technology allows dental restorations to be created with exceptional accuracy, ensuring a perfect fit, natural color, and comfortable feel.

Restorations that traditionally took days or weeks can now be designed and milled within hours, enabling single-visit treatments.

Patients benefit from more comfortable digital impressions and faster treatment times, improving overall satisfaction.

Dental CAD/CAM milling machines have transformed dental restoration by offering unmatched precision, speed, and patient comfort. From digital impressions and design to automated milling, the process is streamlined to produce high-quality, customized restorations efficiently.

If you want to elevate your dental practice with advanced CAD/CAM technology, our state-of-the-art milling machines deliver precision, reliability, and ease of use. Contact us today to learn more about how our solutions can improve your workflow and patient outcomes.

At HONCHON, we specialize in developing high-precision dental CAD/CAM milling machines that meet the demands of modern dental laboratories and clinics. Our machines are compatible with mainstream open systems and offer stable performance for zirconia, PMMA, wax, and glass ceramic milling. Backed by over 10 years of manufacturing experience and international certifications (,FDA, ISO 13485), we support OEM/ODM and provide full after-sales service worldwide.

Contact us today to learn how our milling solutions can improve your workflow and patient satisfaction.

Fast delivery | Global support | OEM available

WhatsApp 8613055185196

email :info@honchon.com