Why choose Honchon as your dental zirconia blanks partner?

1. Honchon is a leading manufacturer and supplier of dental zirconia blanks in China; our factory has 14 years of experience in production, and the process box equipment is always updated!

2. We have a mature distribution network with customers all over the world; we know very well the problem points that our customers need to solve urgently; we are fully familiar with the rules of each country's imports; and we can provide high-quality solutions for dental laboratories, clinics, and dealers all over the world.

3. After years of accumulation, we have spent a lot of time and effort on factory hardware and staffing, and now we have a modern factory of 8,000 square meters.

4. HONCHON has been certified by ISO 13485, FDA, and provides high-quality zirconia blocks to customers in more than 120 countries.

Our Advantage:

High quality: made from the best zirconia powder in China, our finished products are excellent in durability, translucency, and biocompatibility.

Advanced equipment: We have purchased cold isostatic pressing machines imported from abroad, and the equipment is currently running smoothly.

Customized Solutions: We can provide customized OEM/ODM services to meet the various needs of various distributors and dental laboratories.

Global Transportation: We provide multiple delivery channels; you can choose air, sea, or land transportation according to the actual needs, safe and efficient.

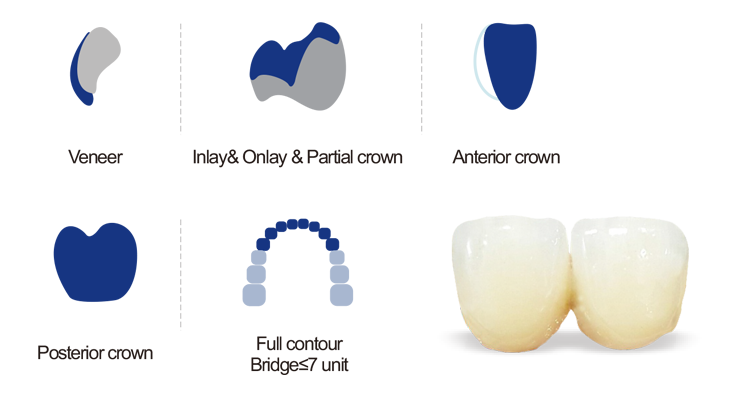

Dental zirconia blanks are pre-sintered zirconia disks. Dental zirconia blanks are mounted in a dental milling machine and, using a CAD/CAM system, are first milled and then fully sintered to create dental restorations such as crowns, bridges, and veneers. Dental zirconia blanks are popular with customers for their strength, natural aesthetics, and biocompatibility and are durable denture restorations in modern dentistry, with higher flexural strength than glass ceramics and better aesthetics than metallic materials.

Crowns and bridges

Implant abutments

Full-contour restorations

Veneers

Inlays

Production process of dental zirconia blanks

1. Raw material procurement Material selection: Use zirconia powder from China National Ceramics.

2. Powder preparation: Mix zirconia powder, stabilizer, and inorganic pigment evenly.

3. Dry pressing: Press the zirconia powder into disc blocks.

4. Cold isostatic pressing: Apply pressure evenly from all sides of the zirconia to make the density of zirconia uniform.

5. Pre-sintering: The zirconia blank is pre-sintered at 1050 degrees Celsius. The whole process takes 4 days.

6. Milling: Mill the zirconia into a predetermined size, such as 98mm or 95mm.

7. Inspection: Fully inspect the zirconia blank according to the process requirements to ensure that the product is 100% qualified.

| Type | Strength (MPa) | Translucency (%) | Shades | Thickness (mm) | Applications |

|---|---|---|---|---|---|

| White Zirconia Blank | 700-1350 | 40-49 | Customizable | 10, 12, 14, 16, 18, 20, 25 | Crowns, bridges, full-contour restorations |

| Pre-Shaded Zirconia Blank | 700-1200 | 40-49 | VITA 16 + 4 | 10, 12, 14, 16, 18, 20, 25 | Quick and efficient restorations |

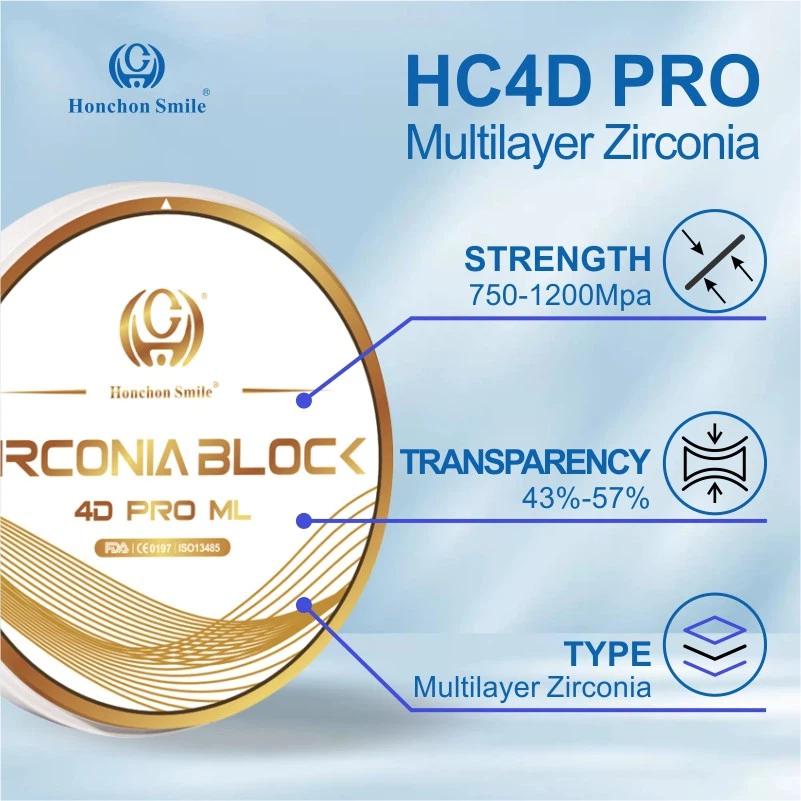

| Multilayer Zirconia Blank | 700-1200 | 43-55 | VITA 16 + 4 | 10, 12, 14, 16, 18, 20, 25 | Aesthetic anterior restorations |

| Gradient Zirconia Blank | 700-1200 | 43-57 | VITA 16 + 4 | 10, 12, 14, 16, 18, 20, 25 | Advanced aesthetic restorations |

Honchon's 8,000-square-meter factory can produce up to 100,000 zirconia blanks per month at peak times, depending on industry conditions and previous years' orders. The factory is equipped with advanced production equipment; our workers are professionally trained; we ensure high-quality delivery from start to finish; regular product orders are shipped within 1-3 working days; customized orders can be negotiated for a delivery period.